• Aquatraz C2 is the result of more than ten years of development work

• The aim of the project is to help solve key challenges related to salmon lice and emissions

Norwegian companies SalMar and Lerøy announced that they are taking a new step in developing the aquaculture of their country through a joint initiative on the next generation of closed production technology, Aquatraz C2. For both companies, this is part of their innovation-driven strategy to develop and test various technologies for the future of aquaculture. If everything goes according to plan, the first fish will be stocked in these units in the first quarter of 2027, with full operations from 2028, assured Frode Arntsen, CEO of SalMar.

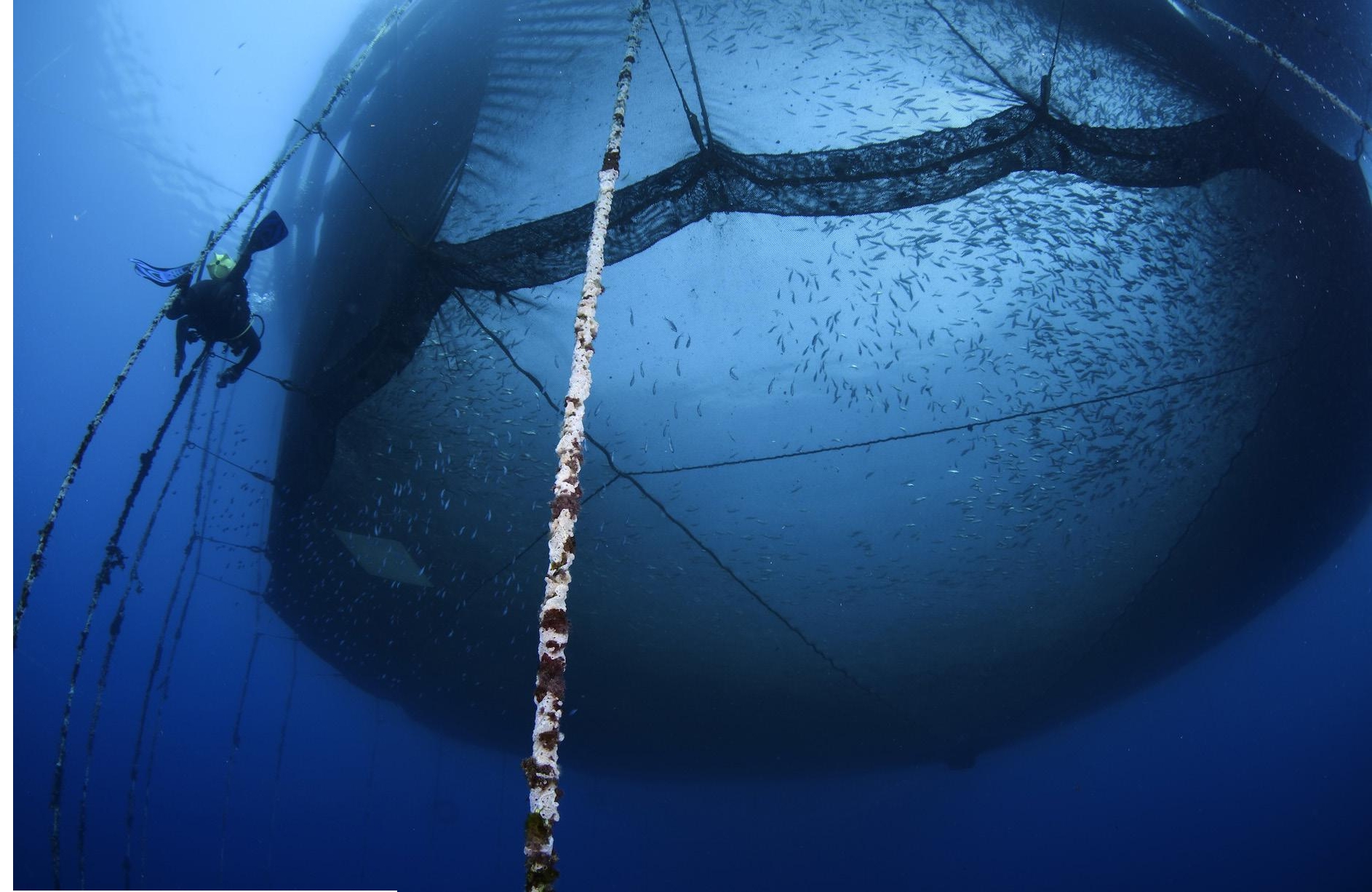

The project includes the construction of six Aquatraz C2 units supplied by Seafarming Systems. Each unit has a water volume of 70,000 cubic meters, with six water intakes at a depth of 35 meters to ensure lice-free water and effective water exchange. This will double the volume of closed production capacity in Norway.

Parts of the construction will be produced in modules in China, while assembly will take place at a Norwegian shipyard. The project also involves technology suppliers from Norway and Europe. The technology has been developed in collaboration with SalMar and Lerøy, building on experience from both the Aquatraz S1 delivered to Lerøy and the first four Aquatraz units developed for SalMar.

New Solutions That Can Contribute to Sustainable Growth

Both companies explained that the aim of the project is to help solve key challenges related to salmon lice and emissions. “We have worked systematically and purposefully on technology development for many years, and have made great progress with submerged cages and testing of semi-closed solutions. Now we are taking this a step further,” explained the CEO of Lerøy Seafood Group, Henning Beltestad.

In a press release, SalMar and Lerøy emphasize that this is not a signal that all production will move into closed systems, but a clear response to the shared ambition of the industry and authorities to develop new solutions that can contribute to sustainable growth in Norwegian seafood production.

According to them, the companies are contributing to important technology development in Norwegian aquaculture and strengthening the Norwegian supplier industry, which is a globally leading innovation driver in the sector. The collaboration provides increased scale, knowledge sharing and reduced risk.

In Parallel with Traditional Equipment

The two companies are clear that traditional technology will continue to be the essential foundation for Norwegian aquaculture, particularly at more exposed locations. Development of traditional equipment will continue in parallel with investments in new technological solutions.

For them, “in this way, Norway can play an increasingly important role in global food production while contributing to solutions for key environmental challenges facing the industry. Our goals are also increased food production, secure jobs and creating industrial ripple effects in Norway. The various production technologies complement and reinforce each other.”

Solid Technical and Biological Foundation

The key, they say, is cages with large farming volume, high water exchange, low energy consumption and competitive cost. “Aquatraz C2 is the result of more than ten years of development work, with continuous improvement and learning from practical operations. This gives us a solid technical and biological foundation for taking the next step in closed-cage development”, details Alf Reidar Sandstad, CEO of Seafarming Systems.

The companies are now preparing for delivery of the cages in about one year, so that sea production can begin. This requires the necessary clarifications and approvals from the authorities. It is crucial that the authorities ensure stable framework conditions during this phase.

Two Companies with a Long History

Lerøy Seafood Group is a world-leading seafood corporation with a history reaching back to 1899. The Group´s core business is the production of salmon and trout, catches of whitefish, processing, product development, marketing, sale and distribution of seafood. Their main office is located in Bergen, but they have fishing vessels and fish farms in operation along the entire coast of Norway.

They have production and packaging plants in Norway, Sweden, Denmark, Finland, France, the Netherlands, Portugal, Spain, Italy, Turkey and Shetland Islands. We also have sales offices in the USA, Japan, China, South Corea, Vietnam and Thailand.

On the other hand, SalMar is one of the world’s leading producers of farmed salmon, with operations spanning Central and Northern Norway, Iceland and offshore through Salmar Ocean. Since their founding in 1991, they say have been driven by «passion for salmon and a commitment to sustainable aquaculture.